Production Process: An Exercise in Efficiency, Cost-effectiveness and Reliability

MJ Cycle has the capability of manufacturing a wide range of metal products for a variety of consumer and industrial applications.

From basic mass produced to high-end precision products, we have the hardware and the technical staff to deliver products that meet originally agreed upon specifications, schedule and budget.

During the development of the product, we will regularly conduct process evaluation and develop quality specifications to ensure that the production process meet strict quality standards. Before production, the Standard Operating Procedures (SOPs) required for each production operation are also formulated to ensure stable production quality.

-

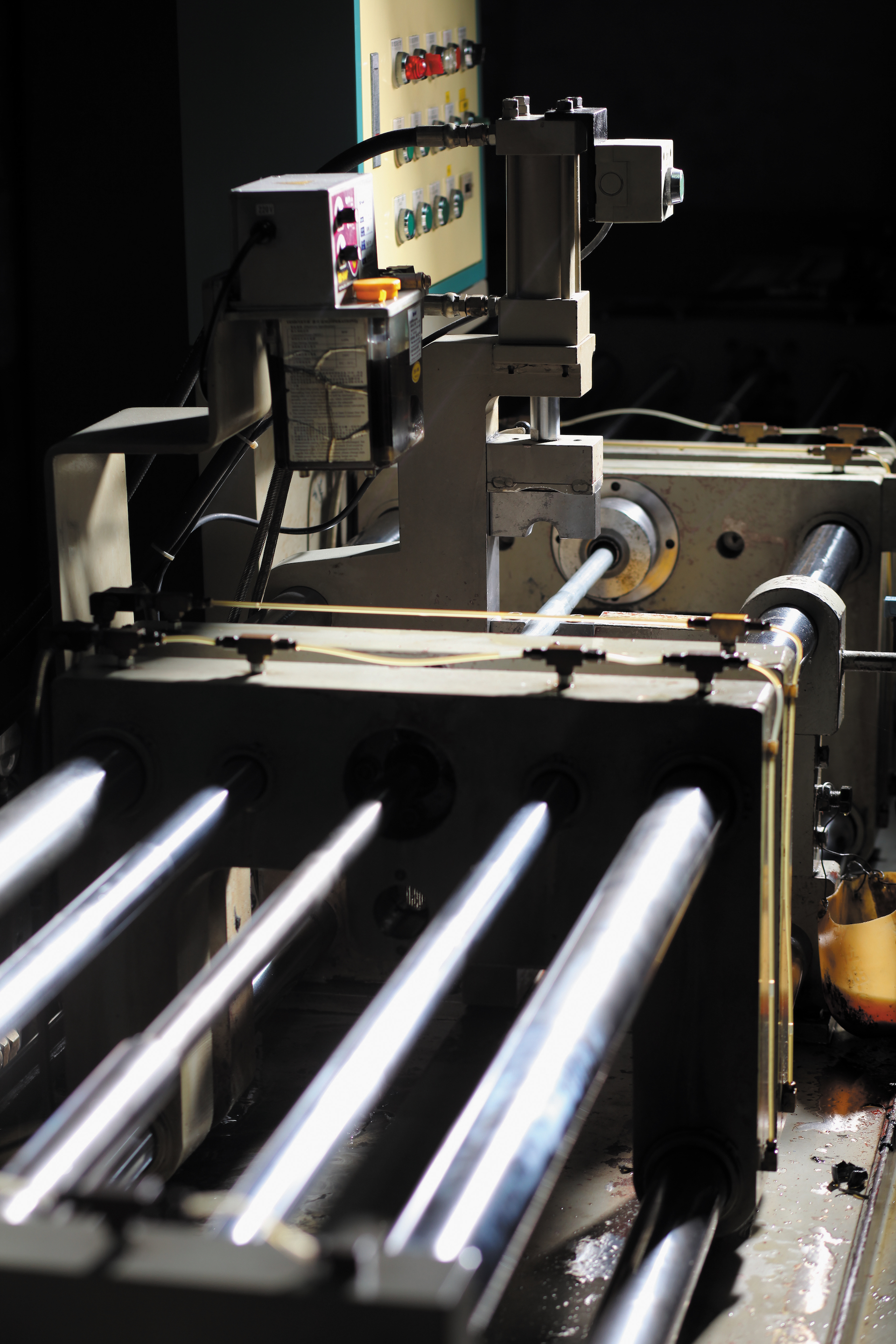

Tube Drawing / Contraction Machines

Mainly used for the forming of different outer diameters of tube fittings and the double butted thickness of the tube.

SPIRAL BUTTING is MJ Cycle’s unique tube processing technology. The advantage of this patented mechanical equipment is that it can replace the traditional multiple tube processes with just a single process to achieve.

-

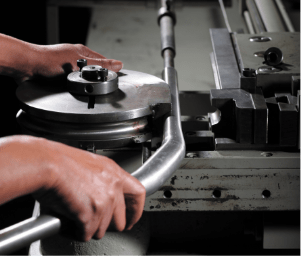

Tube Bending Machines

MJ Cycle has a variety of tube bending machines, whether for a cone tube or a single OD tube, there’s a suitable specialized equipment for the task

-

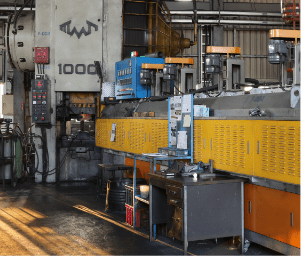

Forging Equipment

Used for forging a variety of raw aluminum alloy materials into consumer and industrial products.

-

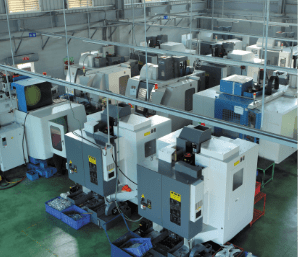

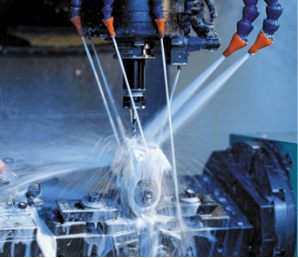

CNC Machines

NJ Cycle utilizes dozens of the latest CNC processing equipment to produce more precise and advanced surface products. Elastic production is carried out for a small number of products that do not have molds.

-

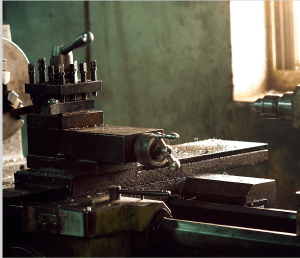

Industrial Drill Press

MJ Cycle currently retains the traditional drilling equipment, which can achieve economical production costs for products that require simple drilling or tapping.

-

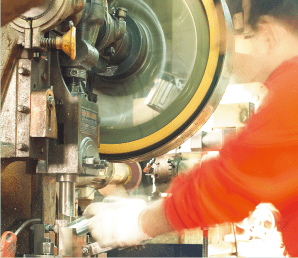

Grinding & Polishing Machines

The grinding and polishing process is mainly used to remove the joint line after the original material is formed as well as eliminating surface flaw after the forming process to give the product an excellent surface quality.

-

Shot-peening And Sand-blasting Equipment

These are used to eliminates the internal stress of the material and also to modify the surface finish of the product.

-

Laser-etching Machine

Used for logos, graphics and other information etched on the product.

-

Decals / Labelling

Decal application using different types of decals as per customer’s requirements.

-

Packing And Assembly

Packing and assembly will be done according to the customer’s requirements.