-

Spiral-Butted Tubing

Game-changing tube extrusion technology applied to all MJ Cycle’s aluminium handlebars: more durable, more strength, less weight.

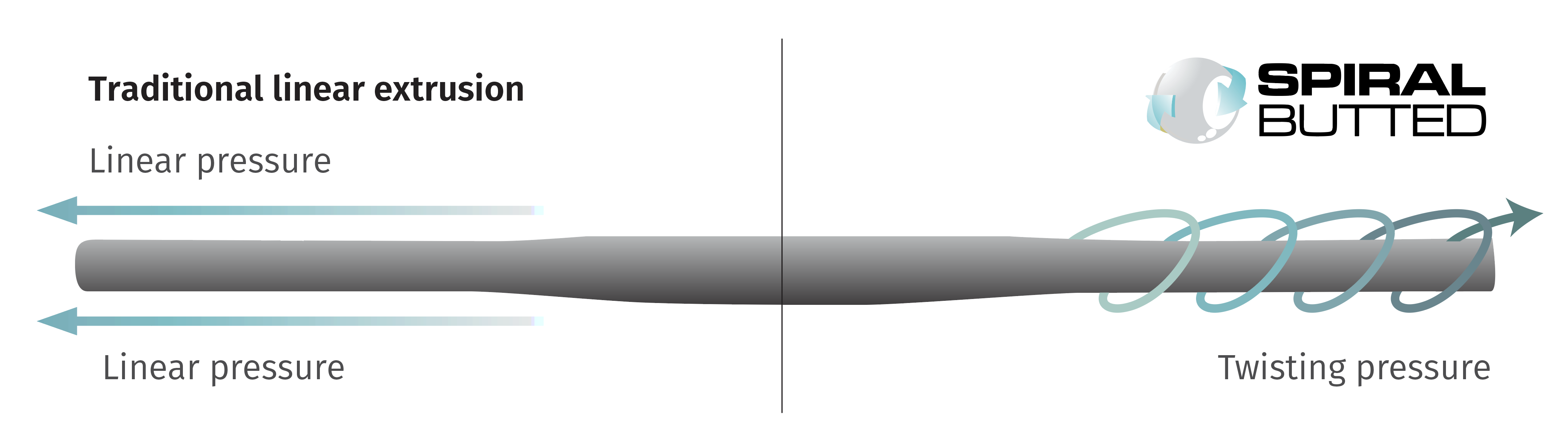

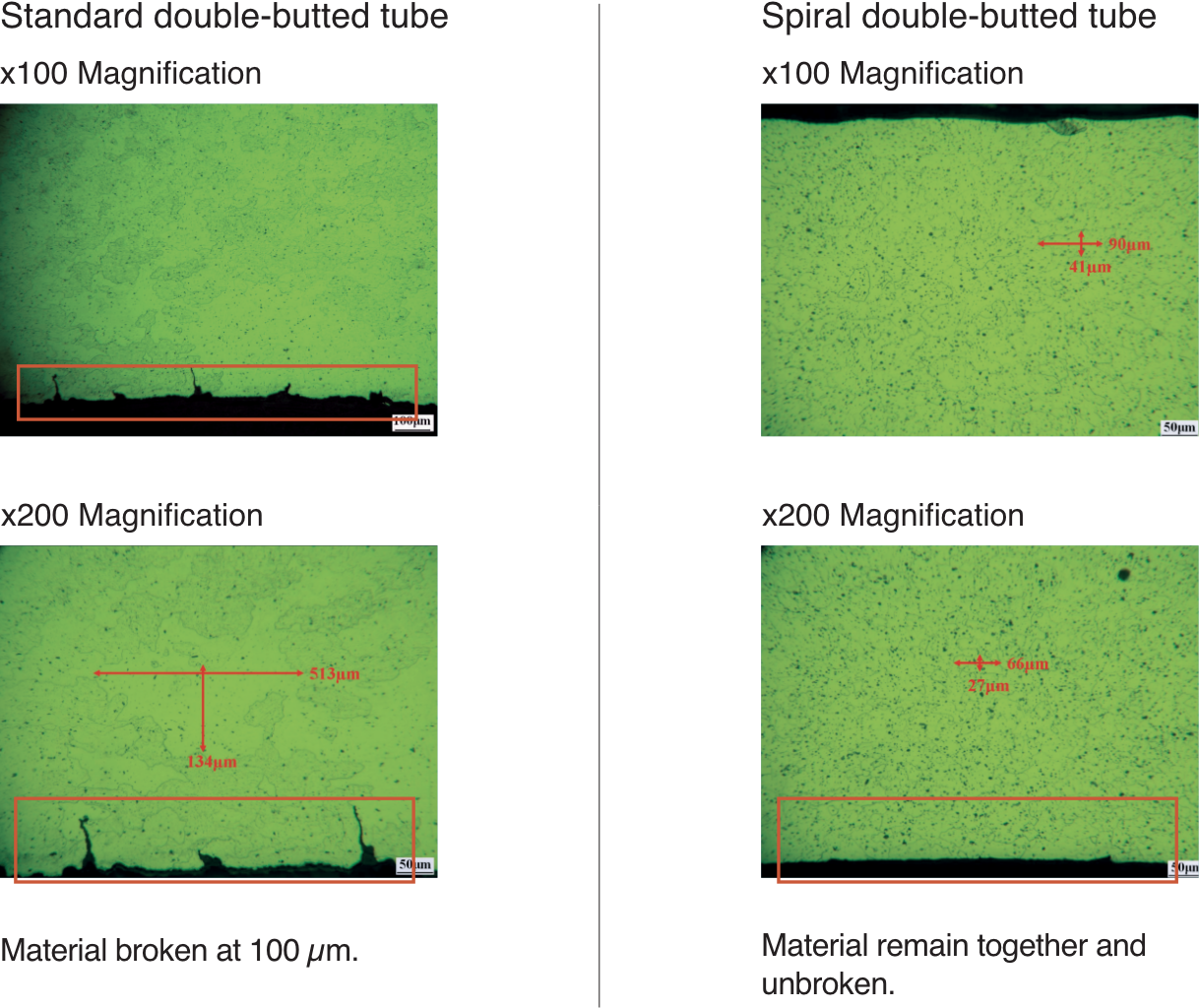

Traditional butting involves a cumbersome 3-step process that does not maximize the potential of aluminum and resulting in compromises. Spiral-butting allows a more dense or compact packing of aluminum material within the tube structure. The result is a significant gain of strength and durability with less weight.

Only MJ Cycle utilizes leading-edge spiral butting technology on handlebars.

Less material & fewer processes mean less pollution.

Less material & fewer processes mean less pollution.Watch the video and learn what MJ Cycle's game-changing SPIRAL-BUTTED TUBING TECHNOLOGY can do for you!

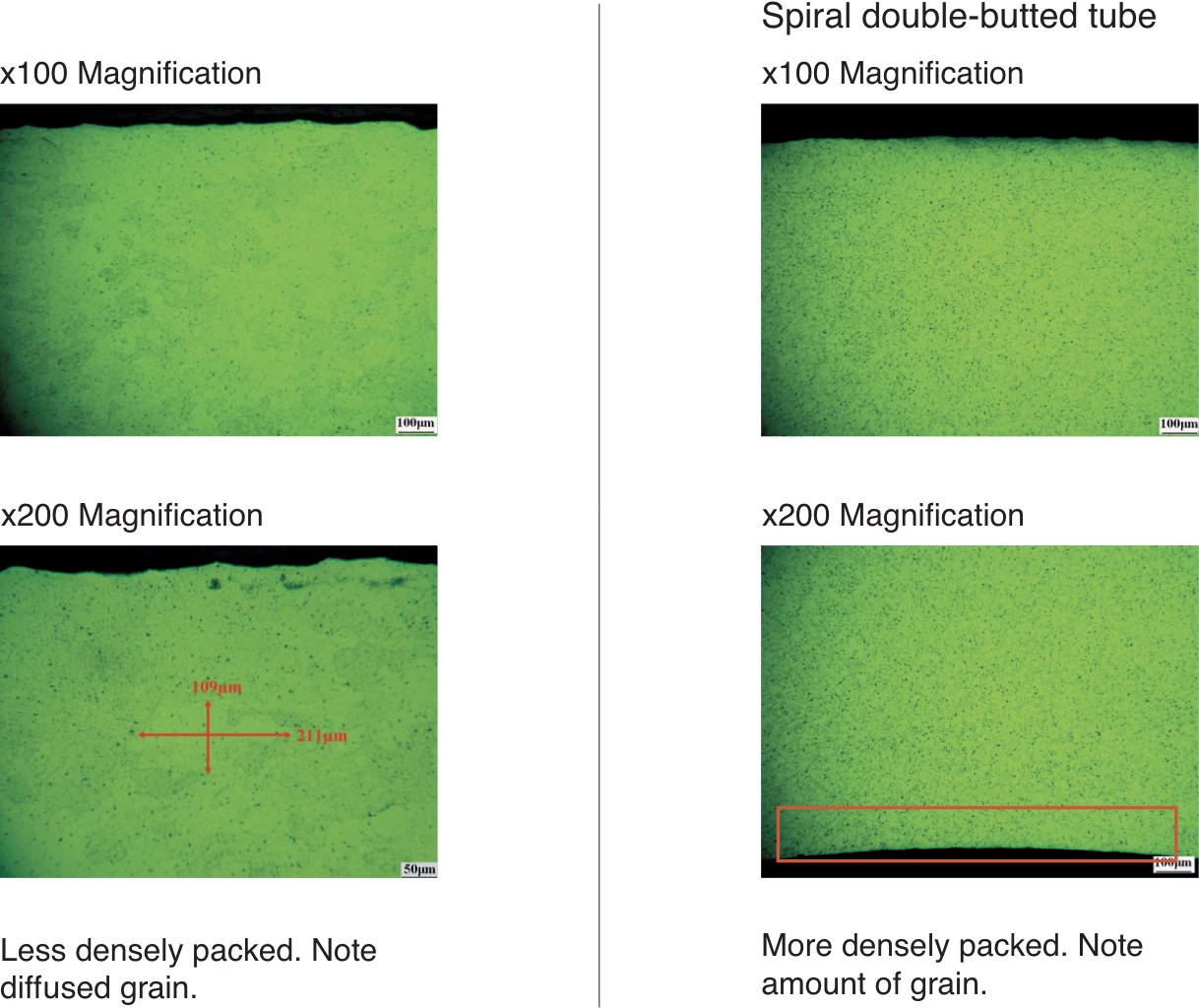

Material Test Report: Grain Size Analysis of Outside Wall Material Test Report: Grain Size Analysis of Inside Wall

Material Test Report: Grain Size Analysis of Inside Wall

-

Butted CrMo

MJ Cycle has already perfected the art and science of butted CrMo tubing, delivering the trifecta of low weight, maximum strength and long-lasting durability. Butted CrMo technology is especially suited for handlebars frequently subjected to intense stress where low weight is also a major consideration.

-

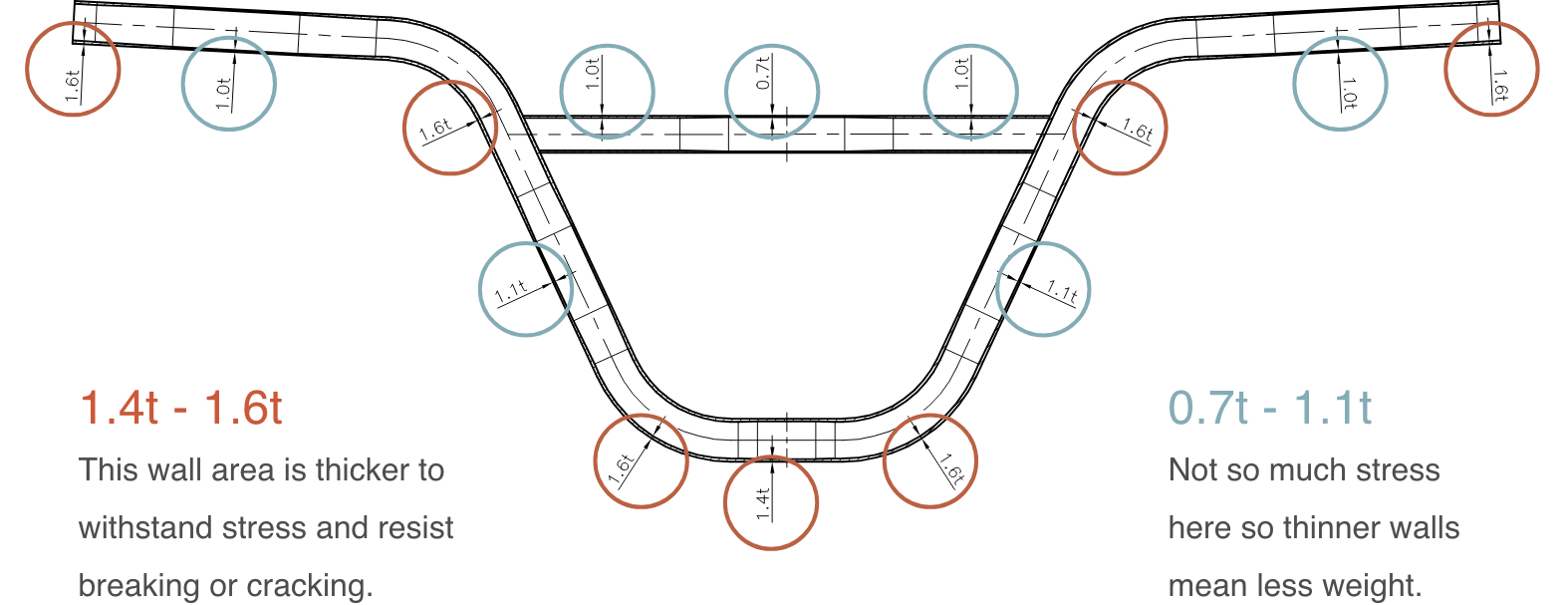

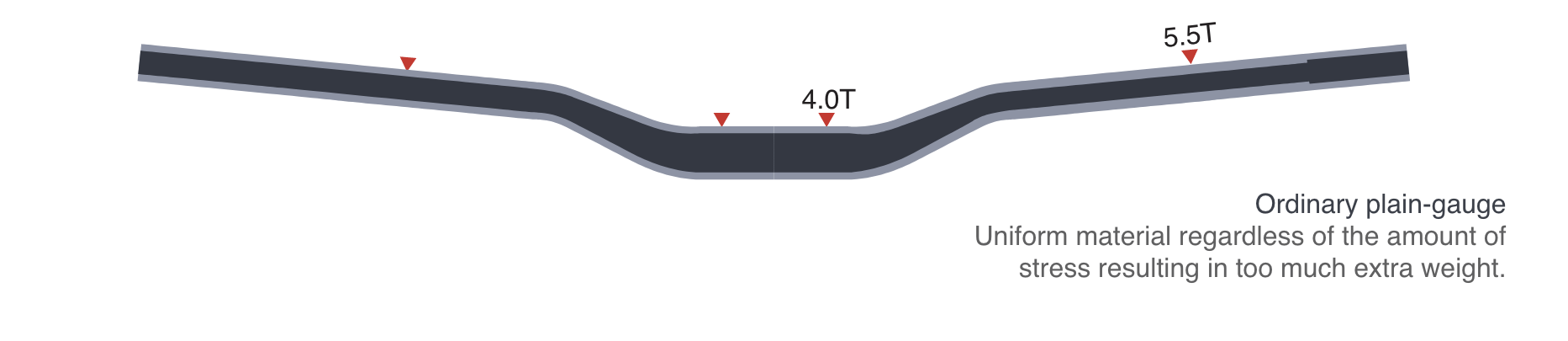

Double-butted Handlebars

A handlebar experiences different stresses and weight loads throughout its length. We pinpoint and calculate the precise amount of stresses a particular area of the handlebar experiences, and add or shave off materials, resulting in a stronger, stiffer, and more durable handlebar than a plain-gauge handlebar, yet with less weight.

Comparative illustration between double-butted and plain-gauge

-

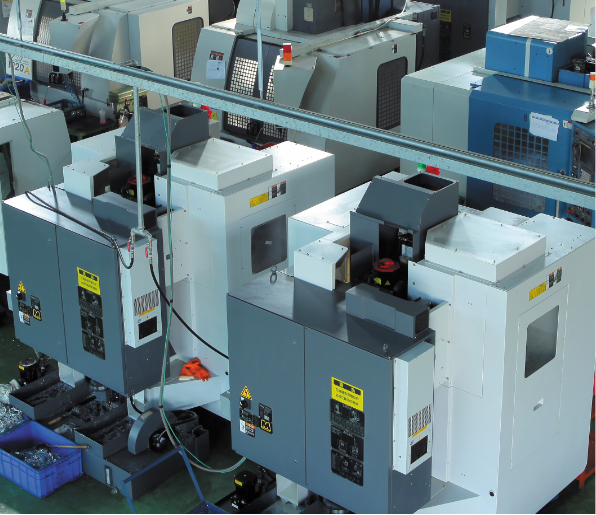

CNC-machining Process

When it comes to uncompromising precision and quality, nothing comes close to CNC-machined products. Through our ICE Corporation, we have been making CNC-machined products for years and are always upgrading our technology and manpower. Currently, our top-of-the-line CNC-machines are capable of the most advanced machining processes. All done in-house.

-

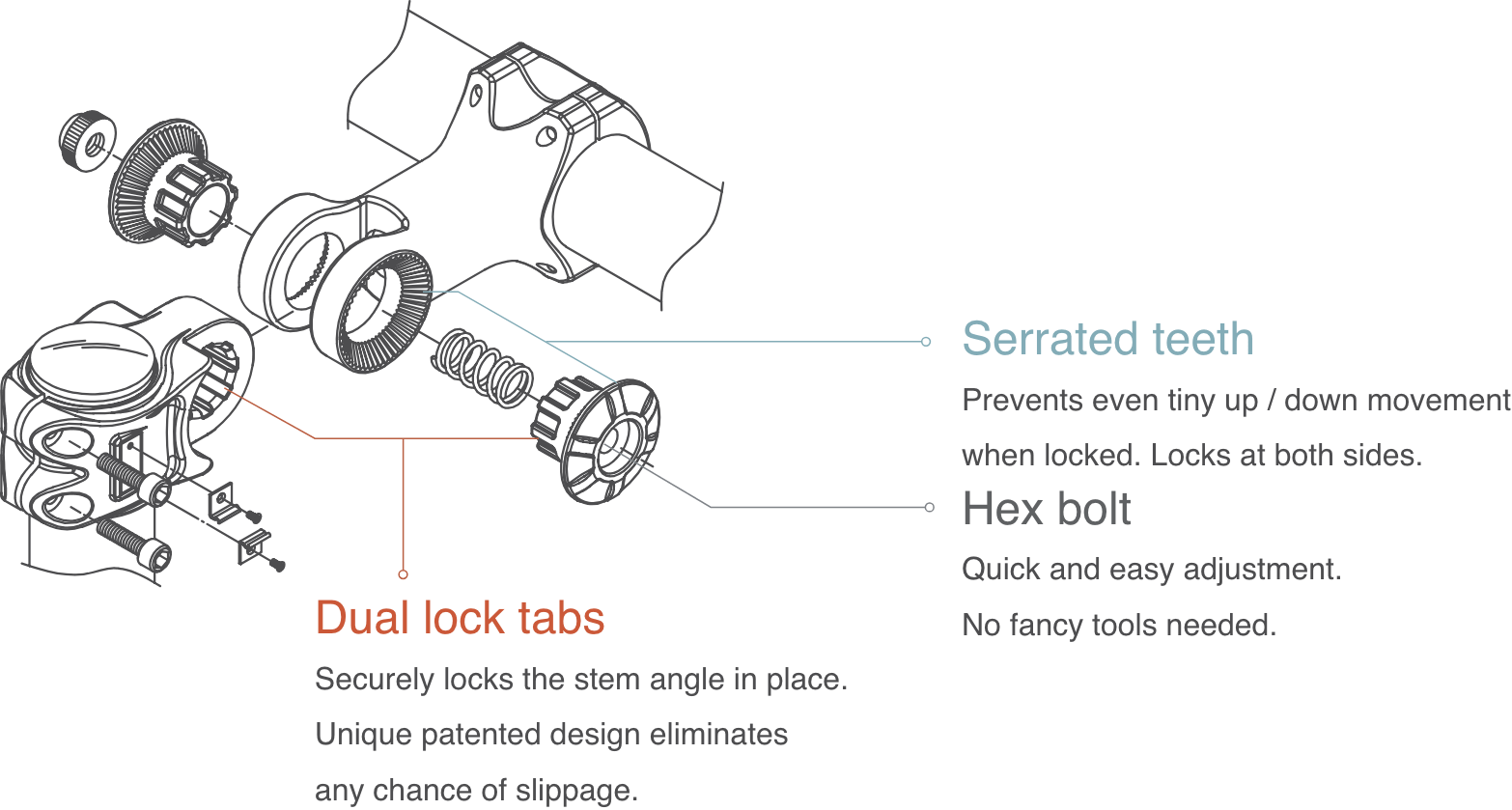

Variable Angle Adjustment

Exclusive patented MJ CYCLE design allows quick, easy and precise stem angle adjustment with just a hex key.

-

Quick Adjust System

Unique one-piece clamping mechanism with twin bolts for a convenient, precise and rapid saddle adjustment.

-

EZ Spring System

Patented design. A single hex key is all that’s needed for a quick and easy seatpost adjustment.